Projects

The research and development work of the research staff is largely financed by third-party funds. Great importance is attached to the balance between basic and application-oriented funding. Fundamental research is mainly funded by the German Research Foundation (DFG). The application-oriented work is mostly supported by third-party funding from the Federation of Industrial Research Associations "Otto von Guericke e.V." as well as by state and federal funding. The chair has manifold cooperations with small and medium-sized enterprises as well as large companies.

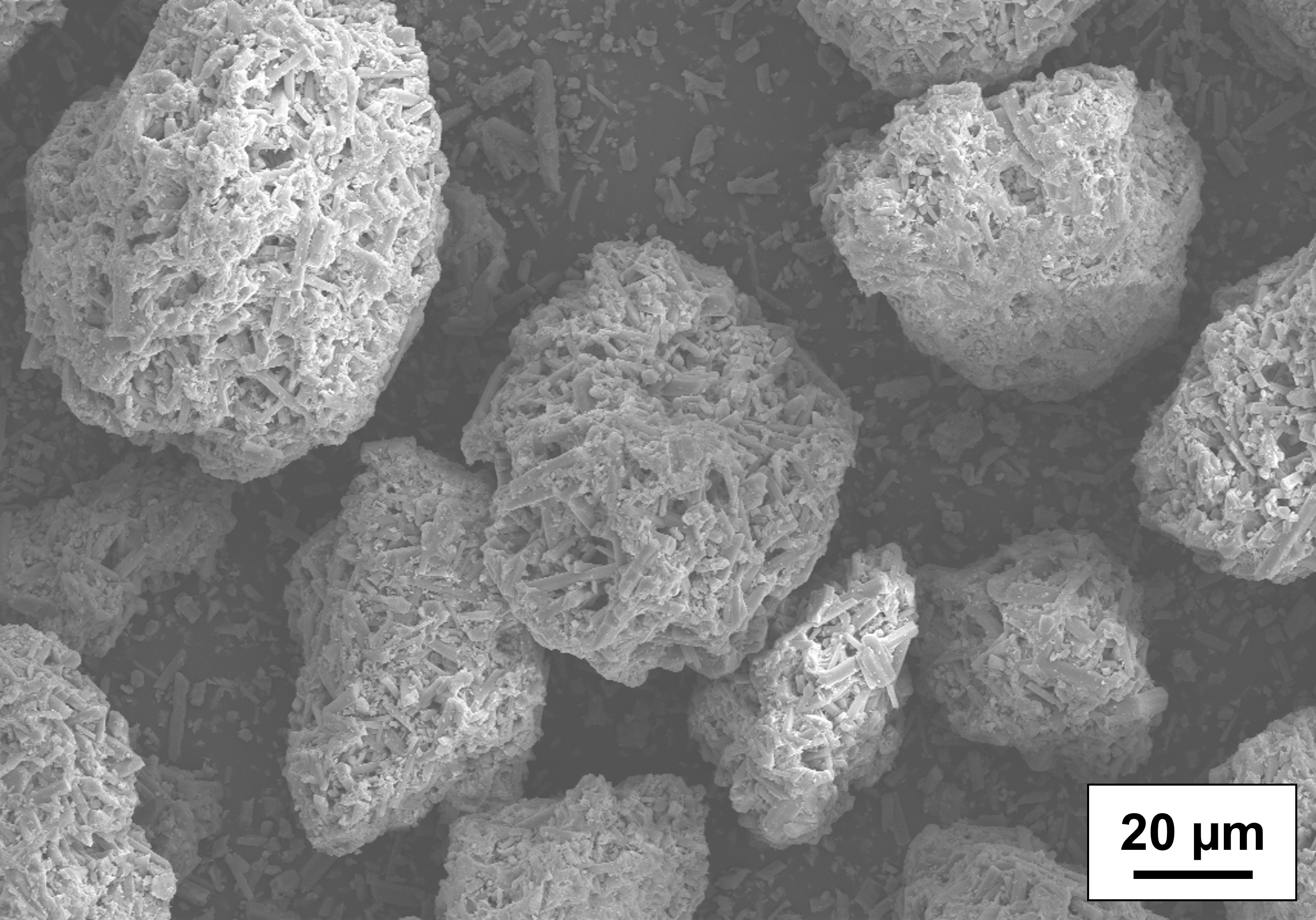

Re- and upcycling of industrial silicon carbide and silicon nitride waste (TRANSFORM)

The industrial green machining of silicon carbide and silicon nitride components produces significant quantities of expensive and high-quality material as waste. Some of this powder is contaminated with foreign ceramic material or other substances. In order to reuse it, a process is to be developed at the Chair of Ceramic Materials whereby it is modified with polysilazanes. (Read more)

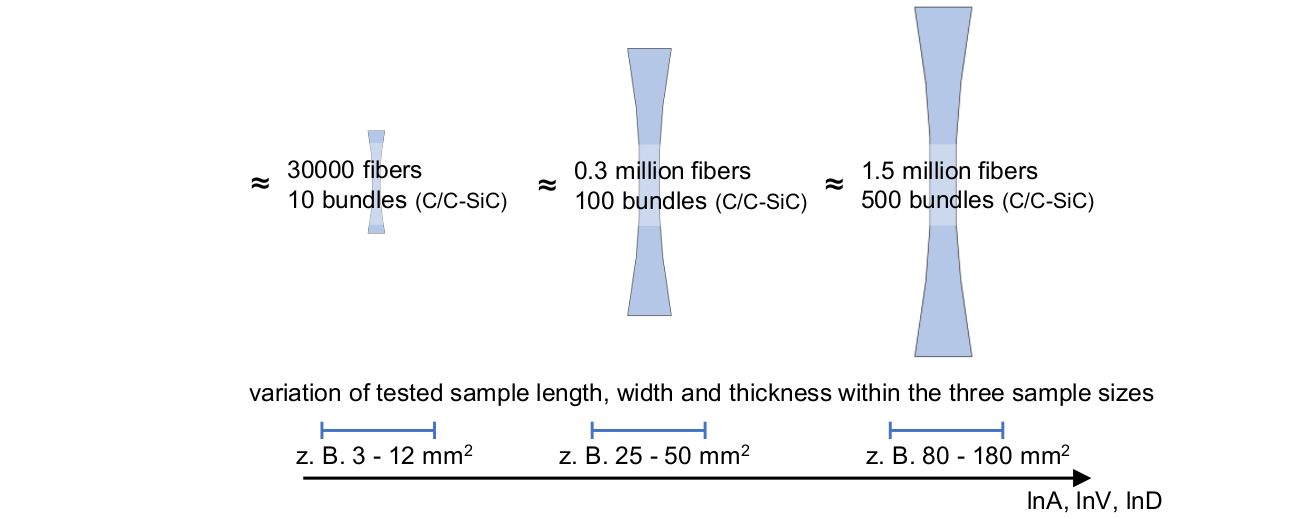

Component size-dependent scaling of the strength of ceramic composites - model assignment and linking of microstructural parameters

Project description: For CMCs, an influence of the component size on the strength can be determined. Therefore, the research project intends to elucidate the expression of size-dependent scaling of strength for CMCs and to derive a description, evaluation, categorization, and prediction through appropriate models. By understanding these size effects, the knowledge on the material behavior of CMCs will be extended and an important building block for the fracture statistical treatment of composite ceramics will be laid. (Read more)

The consequences of novel carbon precursors and efficient process control on the sustainability of composite ceramics and their thermomechanical properties

Project description: The use of composite ceramics can overcome the disadvantages of monolithic ceramics, as they have high damage tolerance, fracture toughness and very high thermal shock resistance. (Read more)

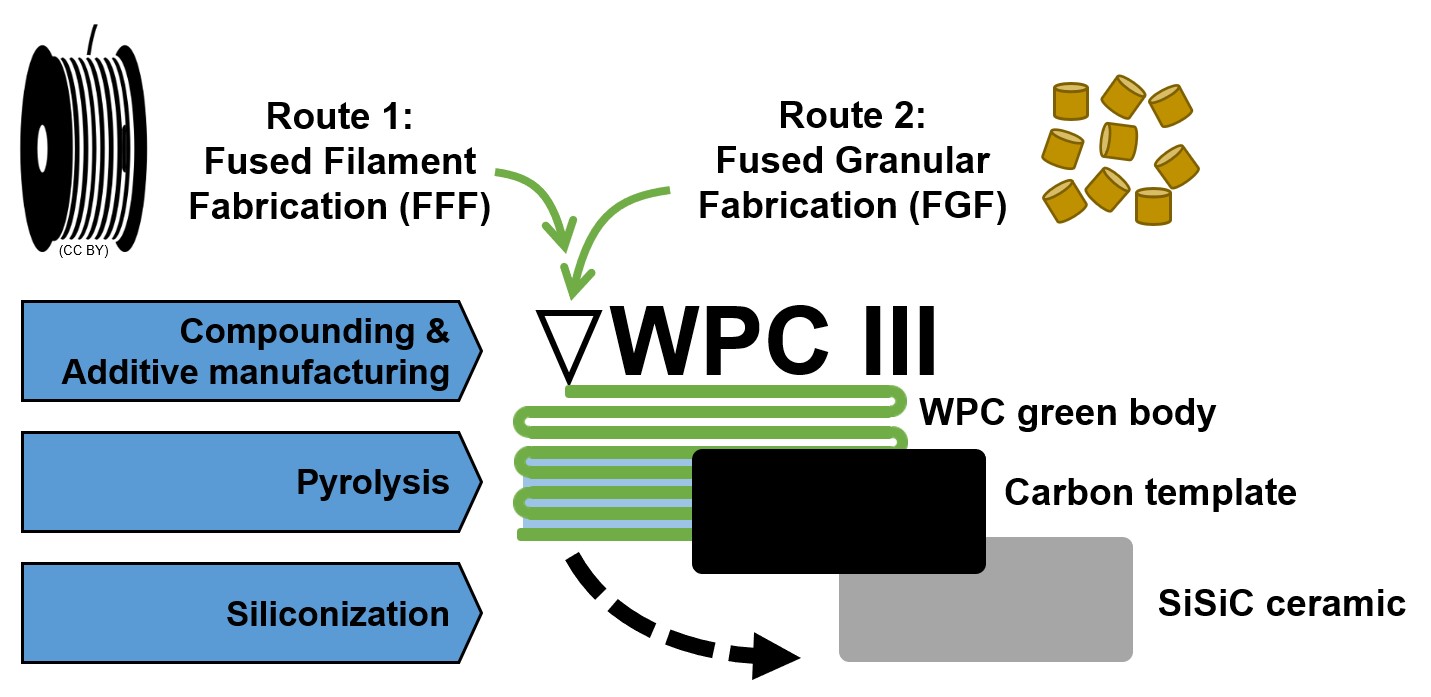

3D printing of WPC to produce near-net-shape complex SiSiC components (WPC III)

Project description: The aim of the research project is to pyrolyze additively manufactured WPC green bodies with the lowest possible shrinkage and to infiltrate the resulting C-template with liquid silicon in order to obtain a high-quality, sustainable, biogenic and thus "green" SiSiC ceramic. (Read more)

Development of friction modifier compositions for C/C materials based on recycled carbon fibers with tailored tribological properties and development of an efficient PIP process for C/C materials (rCFric)

Project description: The aim of the project is to develop a new process chain and a know-how catalog for sustainable C/C materials in friction applications. For this purpose, recycled carbon fibers (rCF) are used for the first time, which significantly determine the structure and properties of the C/C material. (Read more)

Energy-optimized godet with ceramic components for processing high-performance yarns (CeraGo HiT)

Project description: godets are key components in filament yarn production. They are heat able rotating cylinders that move the filaments through the textile machines. The aim of the project is to develop a new generation of godets characterized by a longer service life, better reliability, thermal stability and energy efficiency, in order to ensure the demanding production of new types of high-performance industrial yarns, such as aramid yarns. (Read more)

Rational design concepts of Engineered Ceramics with Integrated catalytically active metal sites for electrochemical Energy conversion (RECIFE)

Project description: Achieving a sufficient, sustainable, emission-free, and environmentally friendly energy system is a top priority for the global energy agenda. In this global effort, material design and electrochemistry play a central role in providing alternative energy solutions. In particular, renewable hydrogen produced by electrolysis is one of the most promising options for efficiently decarbonizing the energy system. (Read more)

High-temperature electrolysis for the production of green hydrogen (HTs: HTEL-Stacks - Ready for Gigawatt)

Project description: In the H2Giga project "HTs: HTEL Stacks - Ready for Gigawatt", we are exploring electrolyte supported cells based on a ZrO2 electrolyte. In this design, the electrolyte is the strength-determining component of the membrane electrode assembly (MEA). (Read more)

Development and characterization of additively manufactured thermoplastic-based short- and continuous-fiber reinforced C/C-SiC composite ceramics

Project description: A process is being developed to make PEEK, thermally at least partially crosslinked or infusible. This can then be used in additive manufacturing to produce 3D bodies that have been designed to withstand loads and are near-net-shape. In addition, the pyrolysis takes place without mold-stabilizing tools or axial weights. (Read more)

Novel oxidation-stable carbon-based multifibrillar fibers with exceptional mechanical properties via electrospinning

Project description: Nowadays, carbon fibers are one of the most important engineering fiber types due to their excellent mechanical properties and light weight. (Read more)

Development of a novel coating system for the oxidative and mechanical protection of carbon materials

Project description: The aim is to develop a ceramic coating system that ensures long-lasting oxidation protection of CFC materials in industrial use at high temperatures. This coating system should seal the surface of the very inhomogeneous, CFC material, have good adhesion, be resistant to thermal shock and wear, and be chemically inert to components during processing. (Read more)

Investigation and evaluation of the component quality, as well as analysis of the occurring damage mechanisms, after the final processing of fiber-reinforced ceramics (MAI CeMCut)

Project description: In this cross-industry research project, the correlation of material and process parameters during the machining of fiber-reinforced ceramics (CMC) is investigated, the damage mechanisms that occur during this process are described, imperfections that arise are classified and their effect on component quality is evaluated. (Read more)

Development of hot gas corrosion-resistant protective coating systems on non-oxide Si-based ceramics for turbine applications

Project description: A significant increase in the efficiency of gas turbines using superalloys cannot be expected, even with complex cooling concepts. However, non-oxide Si-based ceramics such as Si3N4, SiC and ceramic fiber composites such as SiC/SiC are suitable for this purpose. (Read more)

Alloys and coatings for space and other extreme applications (EXTREME)

Project description: Materials and coatings that need to withstand extreme corrosive, thermal and abrasive environments are in rapidly growing demand. Strikingly, the challenges associated with severe environments transgress a multitude of applications such as aerospace and space applications, medical implants and metallurgical processes. (Read more)

Formation of thermally induced crack patterns in anisotropic, fiber-reinforced composites with a brittle matrix

Project description: The subject of the research is the characteristic, thermally-induced crack patterns in anisotropic, fiber-reinforced composites with brittle matrix. The crack pattern formation is investigated both directly in experiments and indirectly, mechanism-oriented with the aid of simulation studies based on the phase field method. (Read more)

Ecotoxicological effects of metallic ultrafine particles on plants (BayÖkoTox)

Project description: The ecotoxicological effects of metallic ultrafine dusts have hardly been researched yet. A major source of metallic ultrafine dusts is road traffic, e.g., through brake abrasion. In the outlined project, metallic ultrafine dusts will therefore be precisely analyzed and the effects of precisely characterized, fine metallic particles of defined origin on plants will be reliably investigated for the first time. (Read more)

Development of ceramic coatings on aluminum and plastics by laser pyrolysis of particle-filled silicanes

Project description: In recent years, it has been shown that precursor technology is very well suited to produce ceramic coatings by means of furnace pyrolysis. However, the required high temperatures allow the production of ceramic coatings only on high melting substrates. Recently, we have successfully demonstrated that laser pyrolysis of precursor coatings can also be used to produce ceramic coatings on steel substrates. (Read more)

Additive Manufacturing of Nano Diamond Silicon Carbide (NanoDiaSiC)

Project description: In the joint project NanoDiaSiC, therefore, a 3D printing process is to be developed by which complex ceramic geometries can be built up. As a demonstrator, a fixture for the semiconductor industry to produce computer chips, a so-called vacuum wafer chuck, will be produced. (Read more)